Details such as the height of the nozzle, ink jet volume, and drying speed all affect the deposition and fixation of the ink. If the parameters are too high or too low, it may result in uneven ink penetration. For each type of fabric, it is necessary to conduct trial printing based on its thickness and absorption characteristics to find the most suitable ink jet volume and drying method.1.Keep a close watch on the ink.

In the printing process, ink serves as the "colorant", and its quality directly affects the final outcome. If the ink does not match the fabric or has unstable quality, it is prone to problems such as excessive penetration and color diffusion. It is recommended to choose high-quality ink that is highly compatible with the equipment model and fabric composition. Additionally, conduct small-scale tests in advance to ensure that the ink's adhesion, stability, and color fastness meet the standards.

2.The pre-treatment of the fabric needs to be precise.

The pre-treatment before printing is equivalent to "preparing the base" for the fabric. If there are residual oil stains, sizing agents, or unevenly applied treatment agents on the fabric surface, it may cause abnormal ink diffusion. Different materials have different requirements for pre-treatment. Some need thorough scouring and cleaning, while others require controlling the concentration of the treatment agent. It is essential to follow the process requirements and ensure that the fabric surface is clean and has good ink absorption performance.

3.Fine-tune the printing parameters to perfection

Details such as the height of the nozzle, ink jet volume, and drying speed all affect the deposition and fixation of the ink. If the parameters are too high or too low, it may result in uneven ink penetration. For each type of fabric, it is necessary to conduct trial printing based on its thickness and absorption characteristics to find the most suitable ink jet volume and drying method.

Details such as the height of the nozzle, ink jet volume, and drying speed all affect the deposition and fixation of the ink. If the parameters are too high or too low, it may result in uneven ink penetration. For each type of fabric, it is necessary to conduct trial printing based on its thickness and absorption characteristics to find the most suitable ink jet volume and drying method.

4.The drying and curing process must not be overlooked.

For the ink to firmly adhere to the fibers, it must undergo sufficient drying and curing. If the temperature is insufficient or the time is too short, residual solvents will cause color migration; conversely, excessive heating may affect the color brightness. Depending on the type of ink, choose curing methods such as hot air, infrared or ultraviolet, and continuously monitor the temperature and time during production.

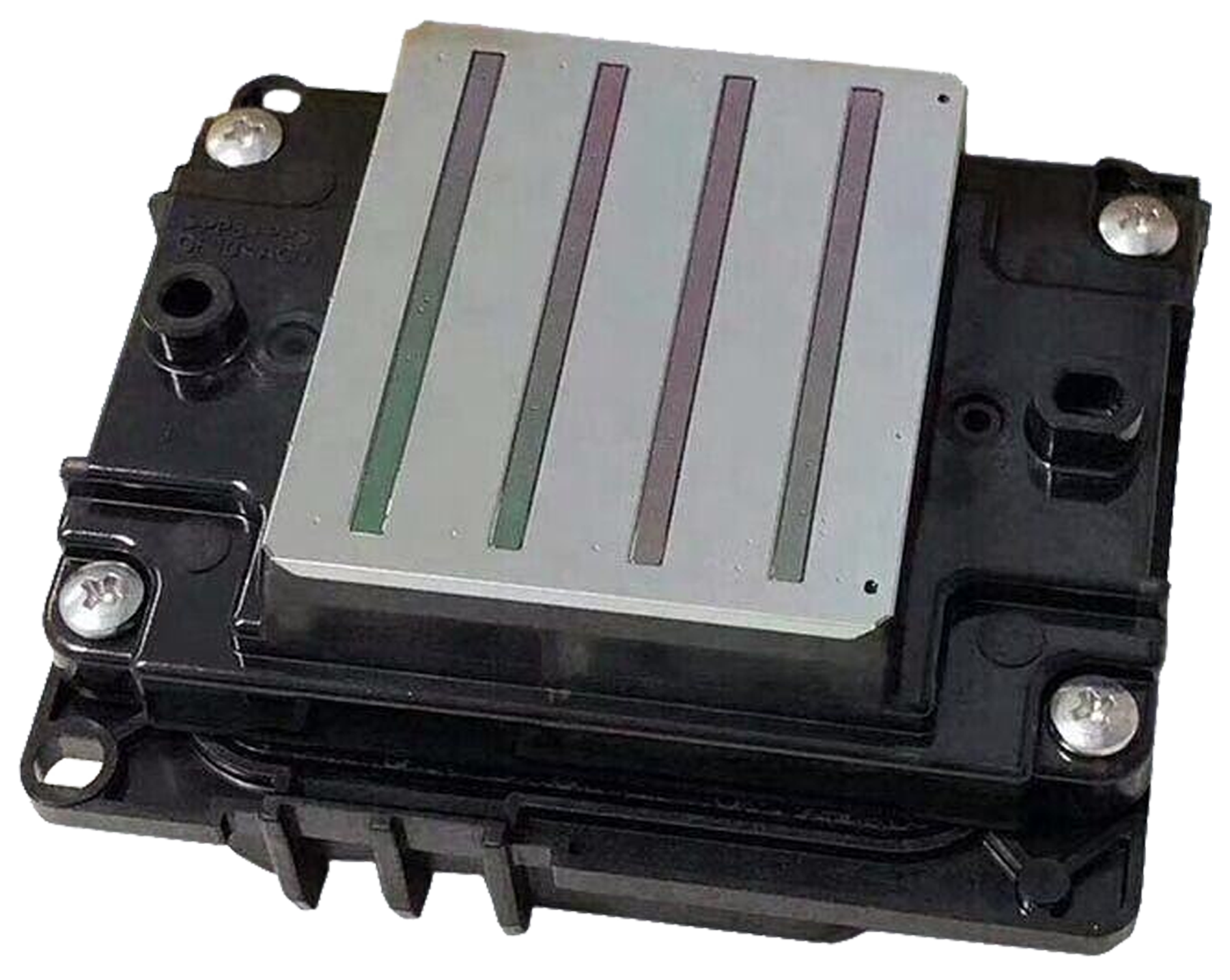

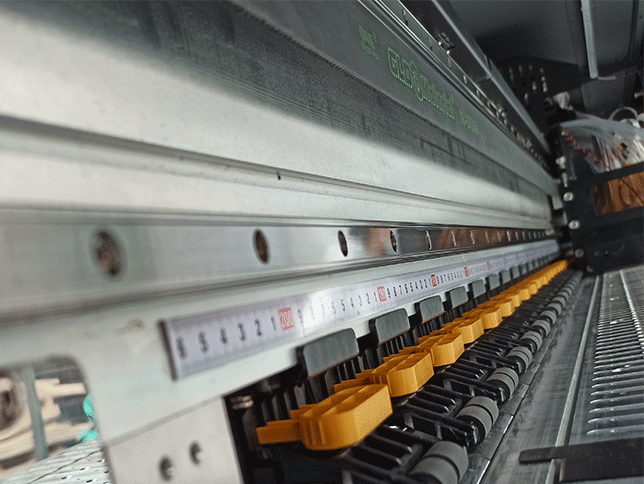

5. Equipment maintenance should be carried out on a regular basis.

After the machine has been running for a long time, the nozzles, guide belts, and other components are bound to accumulate dust or ink stains. These will interfere with the inkjet accuracy and indirectly cause color bleeding. Establishing a regular maintenance plan and conducting cleaning and maintenance according to the manufacturer's instructions can keep the equipment in the best working condition, thereby reducing the risks.