Overview of DTF Printing Technology

DTF (Direct to Film) printing is a rapidly emerging technology in the textile printing industry. Unlike traditional screen printing or heat transfer printing methods, DTF printing simplifies the process flow and reduces costs. It prints the design onto a dedicated transfer film and then uses a hot press to transfer the design onto the fabric, ultimately presenting a high-definition and vibrant printing effect.

2. Workflow of DTF printing on fabrics

-Design Production: First, use graphic design software (such as Photoshop or Illustrator) to create the required design and save it in an appropriate format (usually PNG or PSD).

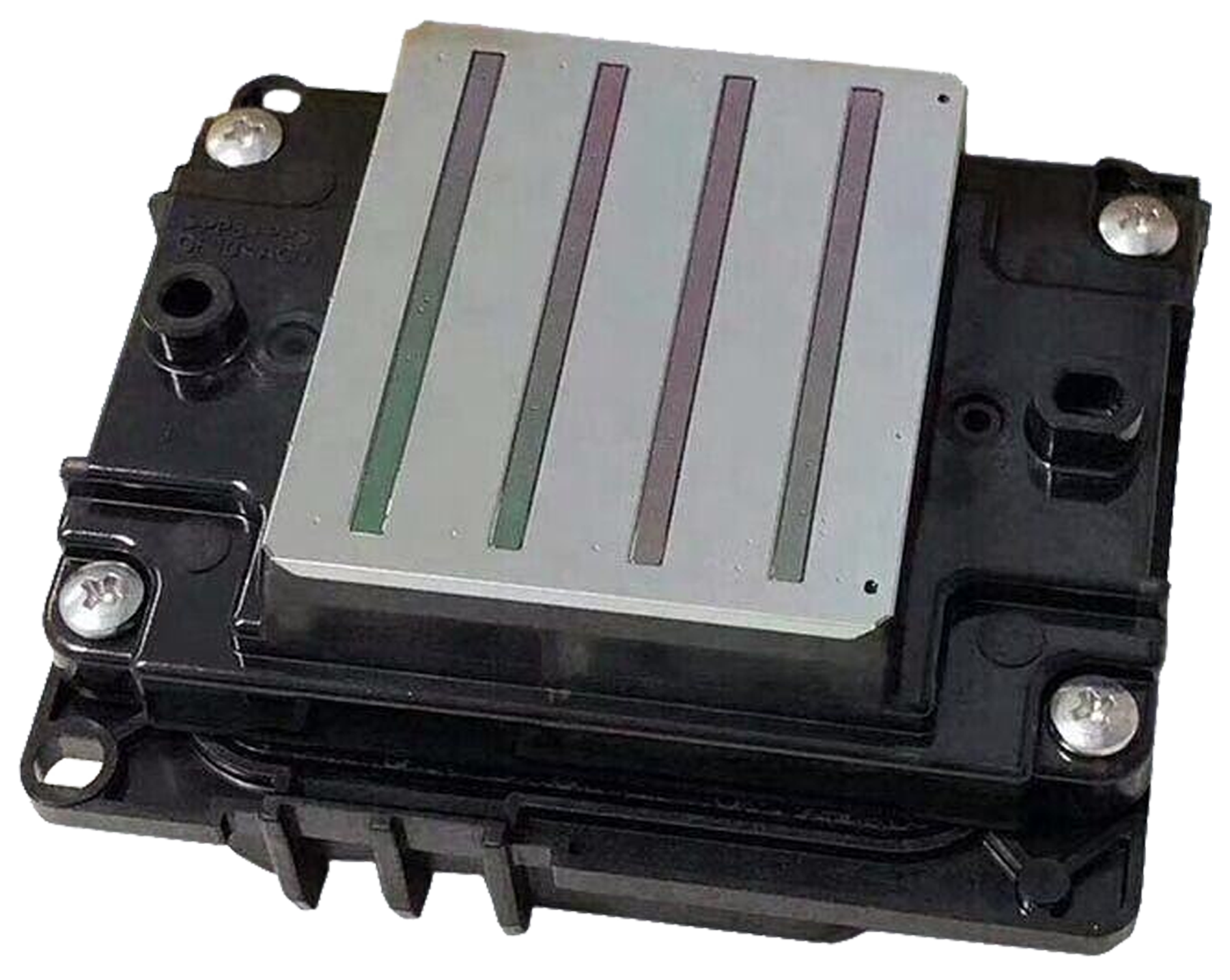

-Design printing: Use a DTF printer to print the design onto transfer film. The printer uses white ink and color ink layered printing to ensure bright colors and comprehensive coverage.

-Powder coating and curing: After printing is complete, apply a layer of special hot melt powder on the film, and then use a heating device to cure. This step ensures that the design can be firmly transferred onto the fabric.

-Transfer to fabric: Place the cured transfer film on the target fabric and use a hot press machine to heat press at a temperature of 150-160 ° C (302-320 ° F) for 10-15 seconds. After cooling, remove the transfer film to reveal the design onto the fabric.

-Cooling and shaping: After the transfer printing is completed, let the fabric cool naturally or use cold air cooling to ensure a perfect combination between the design and the fabric, thereby improving durability and washing performance.

3. Advantages of DTF printing on fabrics

-High resolution and color reproduction:

DTF technology can achieve high-definition printing effects, bright colors, and accurately reproduce complex multi-color designs, especially suitable for art works with complex details.

-Suitable for various fabrics:

Unlike DTG (Direct to Garment) direct spray printing, which is mainly suitable for cotton fabrics, DTF printing can be used for various materials such as polyester, nylon, blended fabrics, denim, leather, etc., and has a wide range of applicability.

-Excellent durability and softness:

Due to the strong bonding between hot melt powder and fabric, DTF printing has the characteristics of wear resistance, wrinkle resistance, and washing resistance. In addition, the design after transfer printing has a soft touch and is not easy to crack, improving comfort.

-Easy to operate, suitable for customization:

The DTF printing equipment is easy to operate and is particularly suitable for small batch and personalized production, such as T-shirts, hoodies, handbags, and pillows. It is highly suitable for the growing demand in the on-demand customized product market.

4. Application scenarios of DTF printing

-Customized clothing:

DTF printing is widely used in the fashion industry for T-shirts, hoodies, and sportswear. Its bright design and rich colors make it very suitable for trendy brands and personalized clothing.

-Home Decoration:

This technology is also applicable to home textiles such as pillows, bed sheets, curtains, and tablecloths, adding creative elements to interior design.

-Personalized gifts:

DTF printing can also be used to customize various gifts, such as handbags, hats, and phone cases, enhancing product value through high-quality printing, and is highly welcomed by consumers.

5. Market potential of DTF printing

With the increasing demand for personalized products from consumers, DTF printing stands out in the textile printing industry due to its high efficiency, flexibility, and low cost. It quickly became the preferred solution in fields such as small batch production, rapid prototyping, and fashion customization. With the development of printing technology and the improvement of materials, DTF printing is expected to have a wider range of applications in various fields such as textiles and decoration.

6. Conclusion

DTF printing technology breaks through the limitations of traditional printing methods and has advantages such as high efficiency, strong flexibility, and environmental friendliness. Whether in the fashion, home decor, or personalized gift markets, DTF printing provides new creative possibilities for designers and manufacturers. With the continuous advancement of technology and changes in market demand, DTF printing will unlock more potential in multiple fields.